Views: 0 Author: Site Editor Publish Time: 20-05-2025 Origin: Site

When it comes to precision manufacturing, the terms "metal stamping" and "metal forming" are often used interchangeably. However, these two processes are distinct, each offering its own set of advantages for specific applications. Understanding the differences between metal stamping and metal forming is critical for selecting the right technique for your production needs. In this article, we'll explore the key differences, benefits, and applications of both processes, with a special focus on how Delixi New Energy Technology (Hangzhou) Co., Ltd. offers cutting-edge solutions that leverage the best of both worlds for superior manufacturing outcomes.

Metal stamping is a manufacturing process that involves placing flat metal sheets into a die and then using high pressure to form the material into a desired shape. The process is typically used to create high-volume parts with consistent precision and accuracy. Some common applications include automotive parts, electronics, and appliances.

Precision: Stamping ensures high accuracy, making it ideal for components that need to fit precisely in larger assemblies.

Efficiency: Due to its high-speed nature, metal stamping is perfect for mass production.

Cost-Effective: Once the die is created, the cost per unit is very low, making it a cost-efficient option for large-scale production runs.

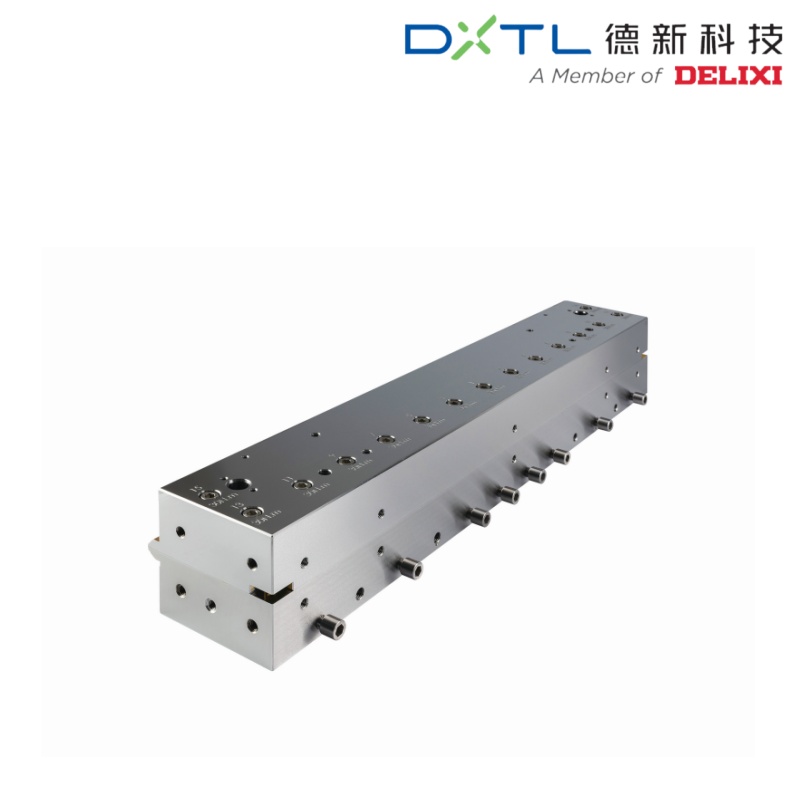

In the metal stamping process, Stamping Dies are crucial. These dies are custom-made to fit the shape and design specifications for each part. Their precision allows for repeatability, which is vital for industries requiring high-quality, uniform components. For companies like Delixi New Energy Technology (Hangzhou) Co., Ltd., utilizing state-of-the-art stamping dies ensures top-tier production quality.

Metal forming, on the other hand, refers to a set of processes where metal is shaped by applying force, heat, or a combination of both without cutting the material. Unlike stamping, which involves high-pressure forming of metal sheets, metal forming techniques such as forging, rolling, and extrusion manipulate the metal into shape.

Material Integrity: Since forming does not cut or remove material, the process maintains the material’s strength and integrity.

Versatility: Metal forming can be used to produce a wide variety of shapes, from complex geometries to large, heavy parts.

Customization: It allows for more intricate and customized designs that might be difficult to achieve with stamping alone.

To provide a clearer picture, let’s compare these two methods across several factors.

Metal Stamping: Offers rapid production speeds due to its high-pressure nature.

Metal Forming: Generally slower than stamping, but the time taken depends on the process used.

Metal Stamping: Extremely cost-effective for high-volume production runs.

Metal Forming: While more versatile, it can be more expensive for smaller quantities.

Metal Stamping: Best suited for thinner materials such as sheet metal.

Metal Forming: Can handle thicker materials and is more suitable for heavy-duty applications.

Metal Stamping: Limited flexibility in terms of customization, but it’s perfect for standardized parts.

Metal Forming: Offers greater customization and flexibility in design, making it suitable for unique or specialized components.

Delixi New Energy Technology (Hangzhou) Co., Ltd. has built a reputation for providing innovative and cutting-edge solutions in the field of coating application, die manufacturing, and precision forming. Their advanced Push-pull Adjustable Coating Slot Die technology is just one example of how they integrate the latest industry trends into their manufacturing processes. By incorporating both stamping and forming techniques, the company delivers highly versatile and high-quality solutions for industries ranging from automotive to electronics.

With a commitment to precision, cost-efficiency, and timely delivery, Delixi New Energy Technology (Hangzhou) Co., Ltd. offers a complete package for clients looking for reliable, customizable, and efficient manufacturing solutions.

Both metal stamping and metal forming have found applications across numerous industries, particularly in high-precision manufacturing fields. Here's a look at some of the industries where these processes shine:

Automotive Industry: Both stamping and forming are used extensively to produce automotive body parts, engine components, and more.

Electronics: From metal casings to internal components, these techniques help create small, intricate parts for electronics.

Aerospace: Precision and strength are paramount in aerospace components, making both processes ideal for creating parts like turbine blades and structural elements.

Understanding the differences between metal stamping and metal forming is crucial for selecting the right technique for your manufacturing needs. Both processes have their distinct advantages and are often complementary. For companies looking for precision, cost-efficiency, and high-quality production, combining these techniques can result in superior outcomes. And for businesses in need of innovative and cutting-edge solutions, Delixi New Energy Technology (Hangzhou) Co., Ltd. stands out as a top choice with their advanced products and services.

A: Metal stamping uses high-pressure to form metal sheets into a desired shape, while metal forming shapes the metal without cutting it, often using heat or force.

A: Metal stamping is ideal for large-scale production due to its efficiency and cost-effectiveness.

A: Yes, metal forming is better suited for thicker materials and heavy-duty applications compared to metal stamping.

content is empty!

Home | About Us | Molds | Precision Automation | Spare Parts | Solutions | Support | News | Contact Us