Views: 0 Author: Site Editor Publish Time: 20-05-2025 Origin: Site

In today’s competitive industrial landscape, quality and precision in manufacturing processes are paramount. One area where this becomes especially crucial is in metal stamping. The right stamping die can make all the difference in the quality, durability, and efficiency of the parts produced. Whether you are looking to manufacture high-precision components for automotive, electronics, or construction, the choice of stamping die is central to achieving superior results.

In this article, we will explore the importance of using high-quality stamping diesand why they are indispensable in the production of premium metal parts. You’ll also learn how Delexi New Energy Technology (Hangzhou) Co., Ltd. offers innovative solutions that ensure the highest standards in stamping processes.

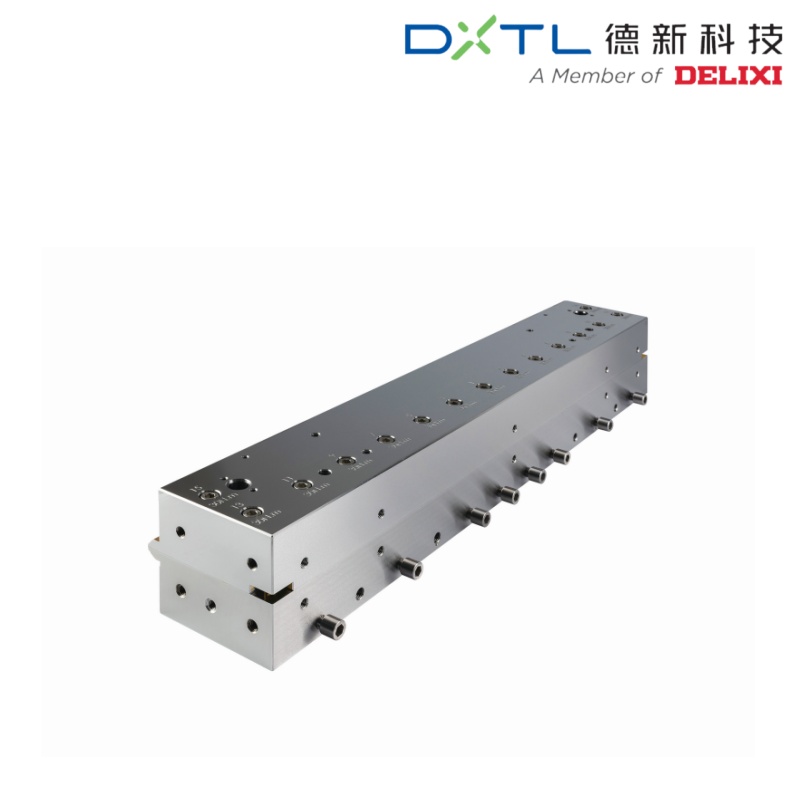

A stamping die is a specialized tool used in the process of metalworking to cut, shape, and form metal sheets into desired shapes. This process is commonly used in manufacturing industries such as automotive, aerospace, and electronics, where precise, high-volume parts are needed.

There are several types of stamping dies depending on the task at hand:

Blanking Dies: These dies are used to cut a flat piece of metal from a larger sheet.

Piercing Dies: Used to punch holes into the metal part.

Forming Dies: These dies shape the metal into a three-dimensional form, like bending or drawing.

Coining Dies: A form of precision die used for creating detailed designs in the metal.

Each type of die plays a crucial role in determining the quality and precision of the stamped parts produced.

Using high-quality stamping dies is critical for ensuring the reliability and longevity of the components produced. A poorly made die can lead to inconsistencies in the stamped parts, causing defects and requiring costly rework.

High-quality dies made with superior materials can ensure the precision and durability needed in today’s fast-paced industrial world. A well-designed stamping die ensures that the parts are shaped consistently and with minimal defects, reducing scrap and maximizing efficiency.

While high-quality stamping dies may come with a higher upfront cost, their ability to produce parts with fewer defects and a longer lifespan makes them a cost-effective solution in the long term. This ensures that manufacturers can meet their production targets without experiencing the delays and added expenses associated with frequent die replacements or reworks.

A high-quality stamping die is essential for improving production efficiency. With the right die, manufacturers can operate at higher speeds without compromising on part quality. This increases throughput and helps meet the growing demands of the industry.

When it comes to precision and performance, Delexi New Energy Technology (Hangzhou) Co., Ltd. stands at the forefront of the stamping industry. Their stamping dies are designed using the latest technology and are built to last, ensuring high efficiency and minimal downtime in production.

Delexi uses cutting-edge technology in the design and manufacturing of their stamping dies, which ensures that every die produced is capable of delivering high-quality results. The integration of advanced design software and manufacturing techniques guarantees that their dies meet the most stringent industry standards.

Understanding that every client has unique requirements, Delexi offers tailored stamping die solutions. Whether it’s a specialized die for a specific part or a custom design to improve production efficiency, Delexi ensures that every customer gets exactly what they need.

Delexi has built a reputation for providing dies that are not only high-performance but also extremely durable. This reliability translates into fewer breakdowns and maintenance costs, allowing manufacturers to focus on their core production without worrying about their tools.

One of the biggest advantages of using stamping dies is their versatility. From automotive to electronics, construction to medical devices, stamping dies can be used to produce parts in virtually any sector. Whether you're producing a small batch of parts or thousands of identical pieces, stamping dies provide the flexibility needed to meet production demands.

As industries push for faster production cycles, the ability to manufacture parts quickly and accurately becomes even more important. Stamping dies offer a perfect balance of speed and precision, enabling manufacturers to deliver high-quality components on time and within budget.

Using stamping dies in manufacturing allows for efficient use of materials. With precise cuts and minimal waste, manufacturers can optimize their use of raw materials, which directly impacts their bottom line. This not only saves costs but also helps meet sustainability goals by reducing waste in the production process.

In the automotive industry, stamping dies are used to create components such as body panels, brackets, and structural parts. The demand for lightweight, durable, and high-performance parts makes precision stamping essential for ensuring the safety and reliability of vehicles.

The electronics industry relies on stamping dies for creating intricate components like connectors, casings, and battery covers. As electronic devices continue to shrink in size and become more complex, the need for precision stamping is greater than ever.

In the aerospace industry, stamping dies are used to produce high-performance parts that must withstand extreme conditions. The precision required for these parts is crucial, and stamping dies are designed to meet these demanding requirements.

High-quality stamping dies are a cornerstone of modern manufacturing. They ensure that parts are produced with precision, durability, and efficiency, making them essential in industries ranging from automotive to aerospace. Delexi New Energy Technology (Hangzhou) Co., Ltd. provides top-tier stamping dies that can meet all of your production needs, delivering custom solutions that guarantee high-quality results every time.

A: A stamping die is used in metalworking to cut, shape, and form metal sheets into specific parts for various industries.

A: High-quality stamping dies ensure precision, reduce defects, and improve production speed, leading to better overall efficiency and lower costs.

A: Delexi offers cutting-edge, durable stamping dies that provide reliable performance, customized solutions, and long-lasting results for any manufacturing process.

A: Yes, stamping dies are versatile and can be used for both large-scale production runs and smaller batches, depending on the requirements.

Home | About Us | Molds | Precision Automation | Spare Parts | Solutions | Support | News | Contact Us