Are you familiar with the vital role stamping dies play in the manufacturing process? If you’ve ever wondered how complex metal parts come to be in industries like automotive, electronics, and packaging, the answer is often through a process involving stamping dies. These critical tools are designed to shape and form materials with precision, efficiency, and speed.

In this article, we will explore what a stamping die is, how it works, and why it’s an indispensable tool in modern manufacturing. We'll also highlight the benefits of using high-quality products, such as those offered by Delixi New Energy Technology (Hangzhou) Co., Ltd., and how they can streamline your production processes.

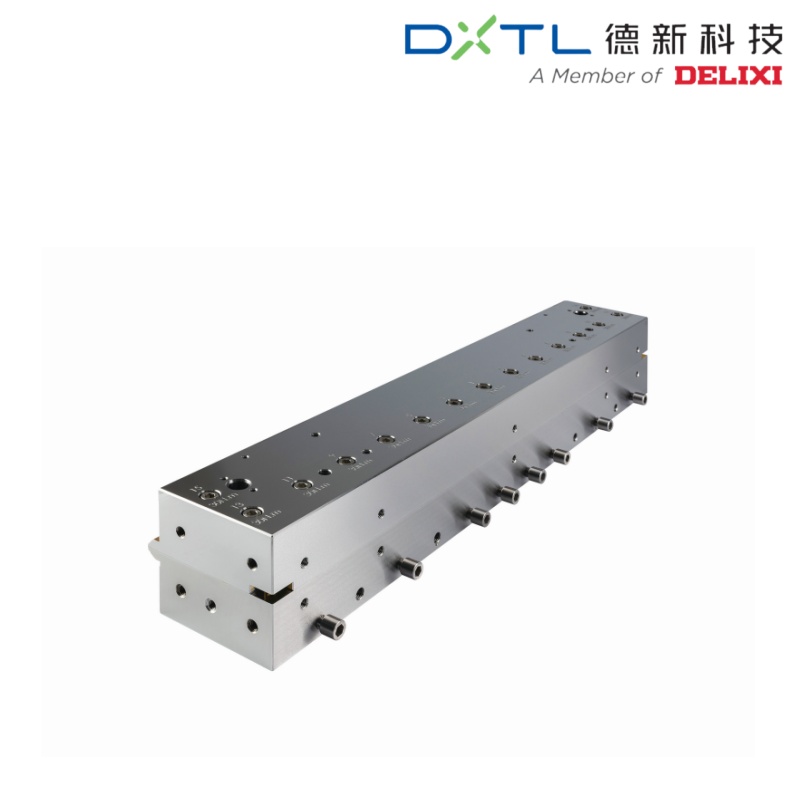

A stamping die is a specialized tool used in the metalworking industry to cut, form, and shape metal into various parts or components. These dies are commonly employed in manufacturing processes such as punching, bending, embossing, and shearing. Stamping dies are typically used in conjunction with a stamping press, which applies pressure to the die, allowing it to shape the metal material into the desired form.

There are several types of stamping dies, each designed for specific tasks:

Cutting Dies – These are used to shear or cut metal parts from a larger sheet.

Forming Dies – These dies shape or bend the metal into desired shapes.

Bending Dies – Designed specifically for bending metal into precise angles.

Blanking Dies – Used to create blanks or pieces of metal that are further processed.

Drawing Dies – These are used to stretch and form metal into deep shapes, like in the production of automotive parts.

Each type of die is tailored to the requirements of the parts being produced and is crucial for maintaining precision and consistency during production.

Stamping dies are vital for ensuring that parts are made with high precision. Whether producing automotive body panels or consumer electronics casings, the dimensions of each part must be exact. A well-designed stamping die allows manufacturers to achieve uniformity and consistency, reducing the chances of errors in mass production.

One of the key advantages of using stamping dies is the efficiency they offer. With the ability to produce large volumes of parts in a short amount of time, stamping dies are an excellent solution for industries that require high-volume production. The automated nature of the stamping process also reduces the need for manual labor, allowing for faster production and lower labor costs.

Stamping dies provide a cost-effective solution for mass-producing metal parts. Since the stamping process is quick and the dies are reusable, manufacturers can produce large batches of parts without significant material waste. This, combined with the efficiency of the process, makes stamping dies an attractive option for industries looking to maintain low production costs.

When it comes to purchasing stamping dies, quality is paramount. Delixi New Energy Technology (Hangzhou) Co., Ltd. stands out in the industry for its reliable and durable products. Their stamping dies are designed with the latest technology and the highest precision, ensuring that every part produced meets the strictest standards.

Delixi New Energy Technology specializes in providing customized stamping dies that meet the unique needs of each customer. Whether you’re looking for a die for a small-scale project or need a large die for mass production, Delixi can provide tailored solutions to suit your specific requirements.

The team at Delixi is committed to innovation and continuously integrates advanced technologies into their stamping die designs. This ensures that their products not only meet current industry standards but also adapt to the latest trends and demands in the manufacturing sector. Choosing Delixi means you’re investing in the future of your production line.

The first step in the stamping die process is the design phase. Engineers work closely with manufacturers to create a die that fits the exact specifications of the parts that need to be produced. This is a crucial step as the design will determine the precision and quality of the final product.

The material used for the die is an important factor in its longevity and performance. High-quality materials are selected to ensure the die can withstand the pressure and wear associated with continuous stamping.

Once the die is designed and the material is selected, it is put into production. The stamping press applies force to the die, shaping the metal into the desired form. This process is repeated for each part to ensure uniformity and consistency.

Quality control is a vital part of the stamping process. Each stamped part is inspected to ensure it meets the required specifications. Any defective parts are discarded or reworked to ensure only high-quality components reach the customer.

One of the latest trends in stamping die technology is automation. With the advent of smart manufacturing, stamping die systems are becoming more automated, allowing for higher efficiency and reduced human error. Automation also allows for faster setup times and the ability to change between different die designs without extensive downtime.

3D printing is starting to play a role in the production of stamping dies. This technology allows manufacturers to rapidly prototype new die designs and make adjustments before committing to the expensive and time-consuming process of traditional die production. As 3D printing technology continues to evolve, it could revolutionize how stamping dies are created.

Smart dies equipped with sensors are being integrated into stamping systems. These sensors provide real-time feedback on the die’s performance, allowing for predictive maintenance and reducing the risk of unexpected downtime. By monitoring the wear and tear on the die, manufacturers can proactively replace or repair components before they fail, ensuring continuous production.

Stamping dies are essential tools in modern manufacturing, offering precision, efficiency, and cost-effectiveness. They are integral to producing high-quality metal parts across various industries, from automotive to electronics. By choosing reliable, high-performance stamping dies, such as those offered by Delixi New Energy Technology (Hangzhou) Co., Ltd., manufacturers can ensure their production processes are optimized for success.

A: A stamping die refers to the entire tool used to shape or cut metal, while a punching die is a specific type of stamping die that is used to punch holes in materials.

A: The lifespan of a stamping die depends on several factors, including the material used, the type of stamping process, and the frequency of use. With proper maintenance, stamping dies can last for many years.

A: Stamping dies are versatile and can be used for various metals, including steel, aluminum, brass, and copper. However, the material’s thickness and hardness may affect the type of die used.

Home | About Us | Molds | Precision Automation | Spare Parts | Solutions | Support | News | Contact Us