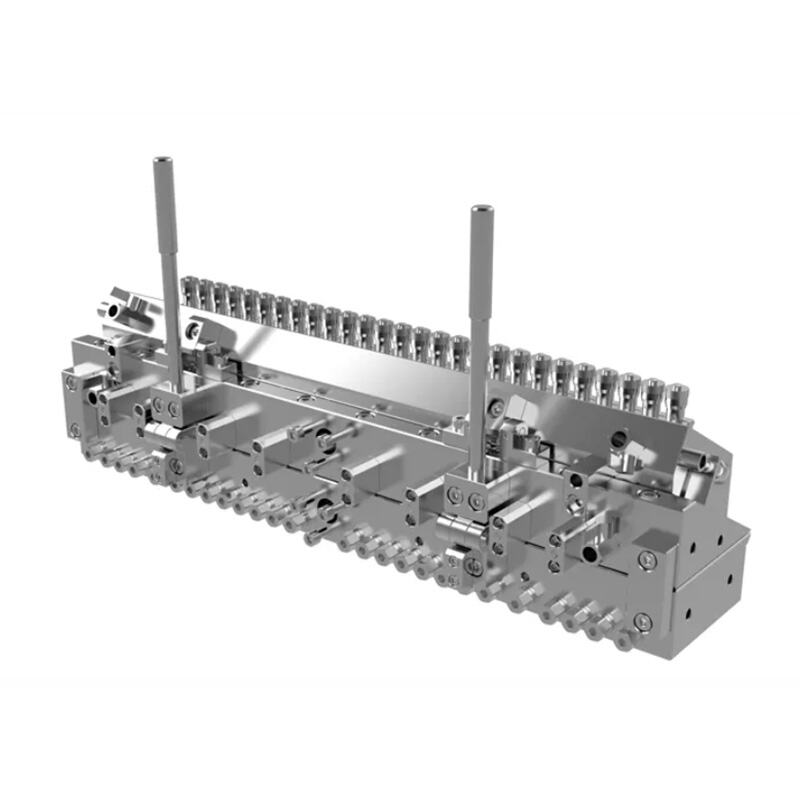

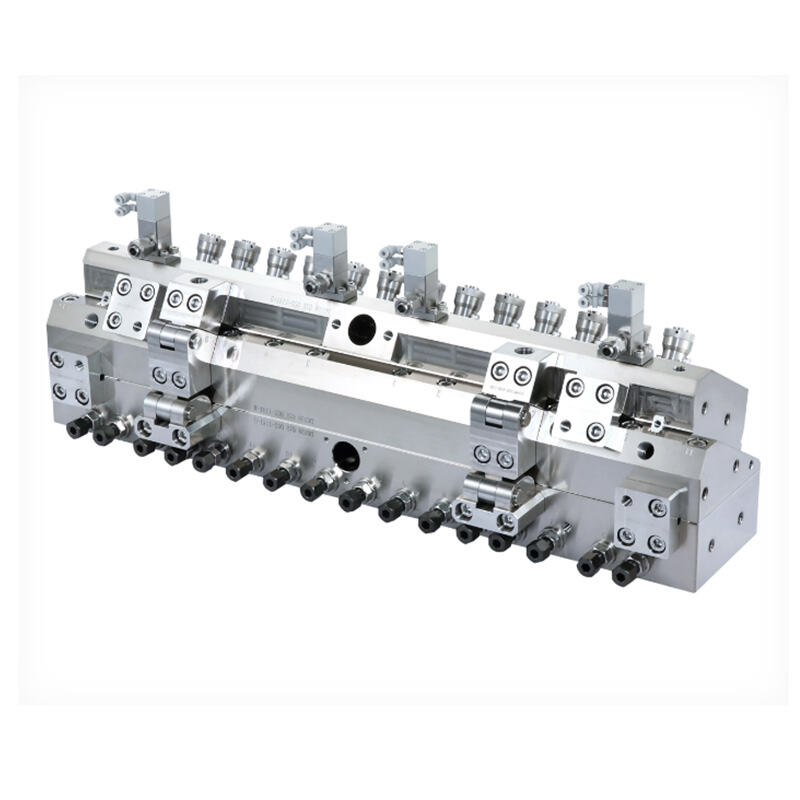

Advanced Slot Die Coater for High-Capacity Battery Electrode Production

Slot Die Coating System is engineered for uniform and consistent deposition of slurry in battery electrode manufacturing. It ensures exceptional coating width and thickness control, which is critical for the performance and energy density of lithium-ion batteries.

- Overview

- Recommended Products

Slot Die Coating System is engineered for uniform and consistent deposition of slurry in battery electrode manufacturing. It ensures exceptional coating width and thickness control, which is critical for the performance and energy density of lithium-ion batteries. Constructed with wear-resistant materials and featuring a modular design, it allows for easy maintenance and quick changeover for different production requirements. It is a key component for R&D and pilot/production lines in the new energy sector. MOQ: 1 set. Customization is available.

| Place of Origin | China |

| Brand Name | DXTL |

| Model Number | DXTL-SD-Series |

| Certification | CE, ISO9001 |

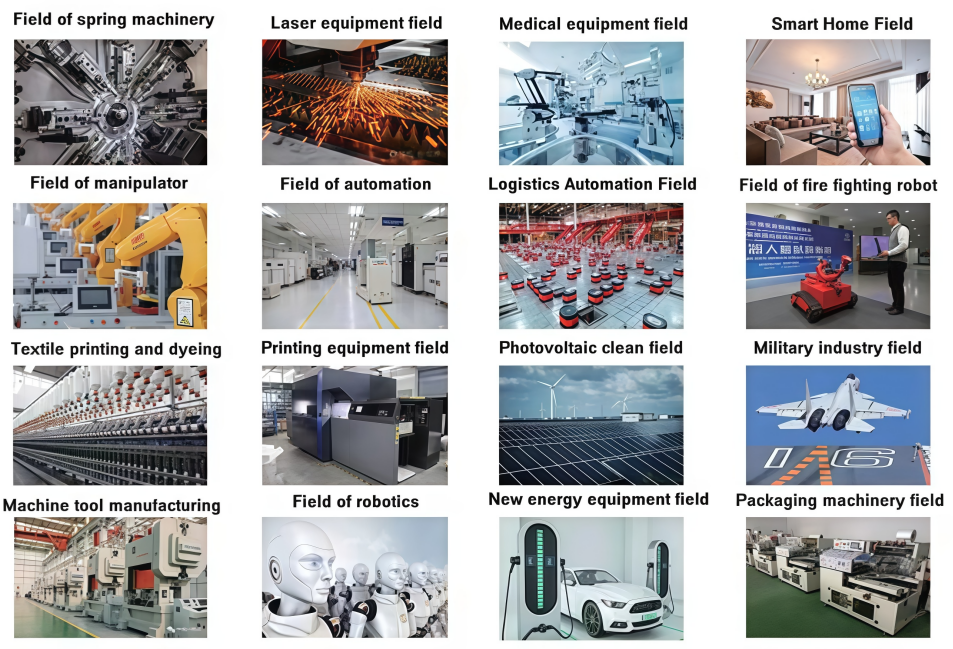

This slot die is primarily used for applying active material slurry onto current collectors (foil) in the production of lithium-ion battery electrodes. It is suitable for both laboratory-scale R&D and industrial-scale manufacturing of batteries for electric vehicles and energy storage systems.

● High Precision: Enables ultra-uniform coating with tight control over thickness and width.

● Superior Flatness & Rigidity: Ensures consistent coating quality across the entire web.

● Wear-Resistant Materials: Extends service life and reduces maintenance costs.

● Modular Design: Allows for easy disassembly, cleaning, and customization.

● Optimized Flow Path: Minimizes slurry retention and ensures smooth operation.

Q: What is a slot die coating system typically used for?

A: It is primarily used in the new energy industry for the precise application of electrode slurry in battery manufacturing.

Q: What materials are the flow path parts made from?

A: Key wetted parts are often made from high-grade, wear-resistant, and corrosion-resistant materials to ensure longevity and slurry compatibility.

Q: Is customization available for different coating widths?

A: Yes, we offer customization for various coating widths and specific application requirements.

Q: What kind of technical support is provided?

A: We provide comprehensive technical support, including installation guidance and operational training, along with a standard warranty.