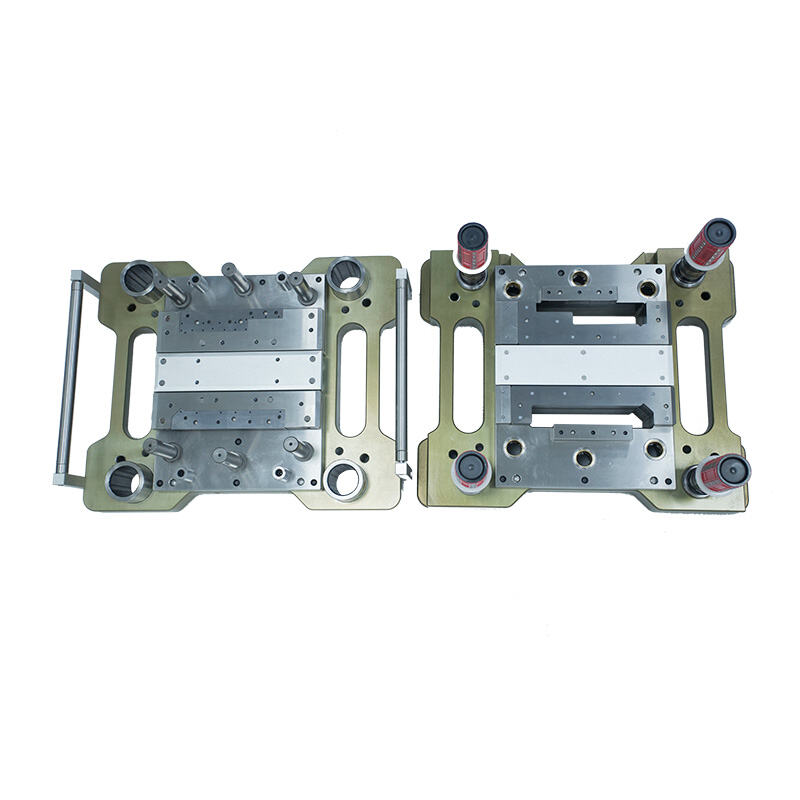

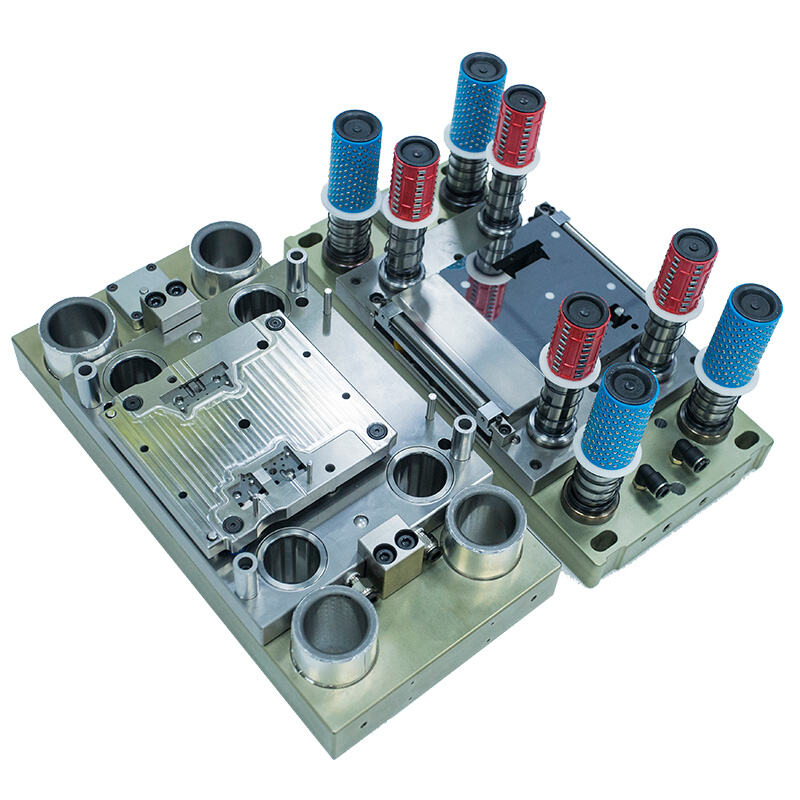

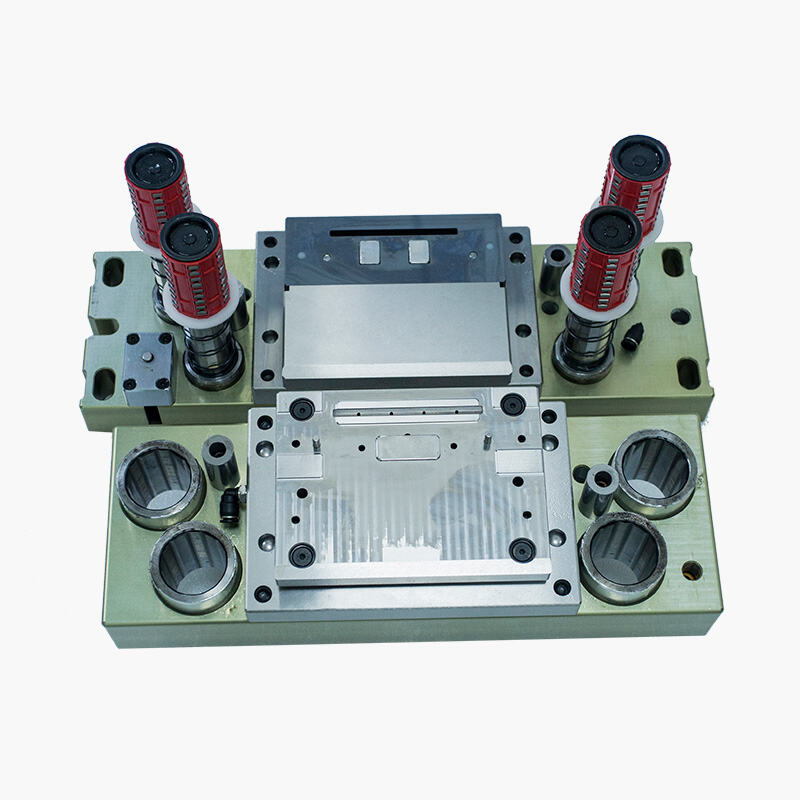

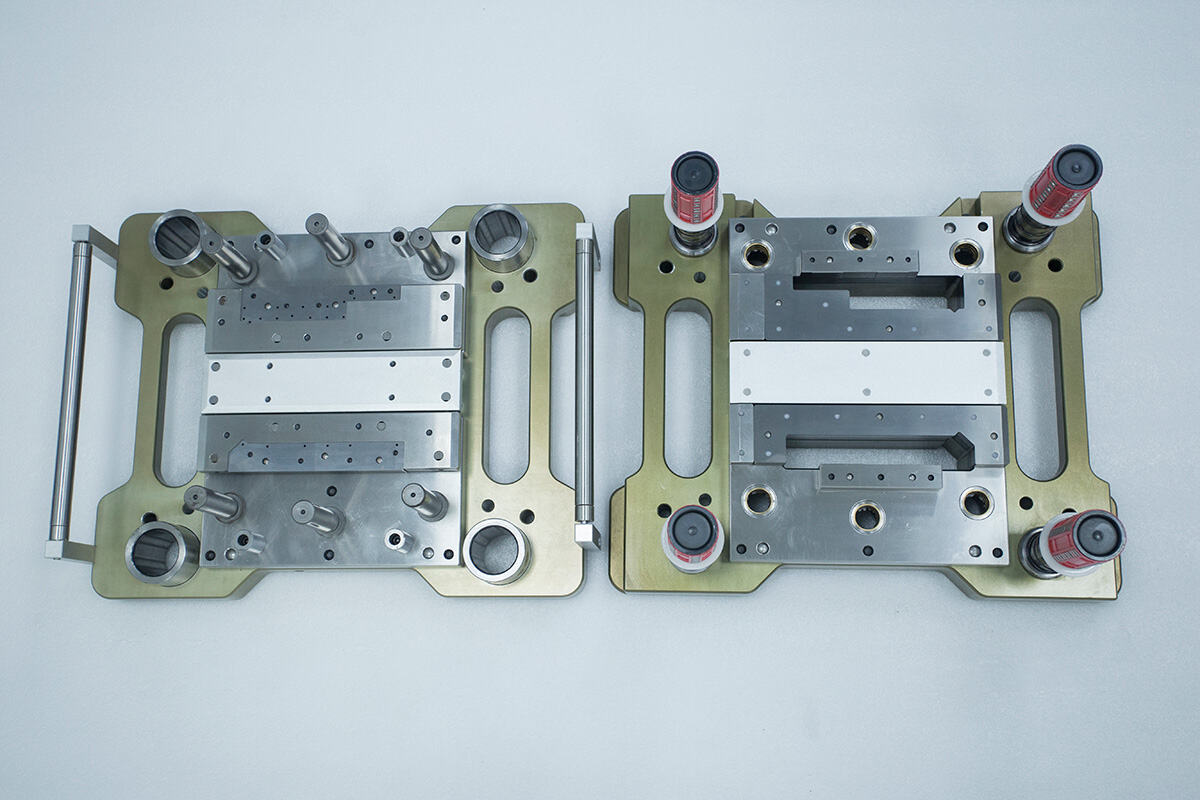

High Precision 3C Consumer Battery Cutting Mold for Efficient Production

Delixi New Energy Technology Co., Ltd.'s 3C Consumer Battery Cutting Mold is designed for precision cutting of batteries used in 3C devices (Computer, Communication, Consumer Electronics). Utilizing high-precision CNC technology, it ensures accurate cuts and smooth edges, enhancing production efficiency and product quality. The mold is made from high-strength alloy steel, offering wear and corrosion resistance, and a long service life. Suitable for automated production lines and supports customization. Welcome inquiries and cooperation.

- Overview

- Recommended Products

Delixi New Energy Technology Co., Ltd.'s 3C Consumer Battery Cutting Mold is designed for precision cutting of batteries used in 3C devices (Computer, Communication, Consumer Electronics). Utilizing high-precision CNC technology, it ensures accurate cuts and smooth edges, enhancing production efficiency and product quality. The mold is made from high-strength alloy steel, offering wear and corrosion resistance, and a long service life. Suitable for automated production lines and supports customization. Welcome inquiries and cooperation.

| Place of Origin | China |

| Brand Name | DXTL |

| Model Number | DXTL-3C-CM001 |

| Certification | CE, ISO9001 |

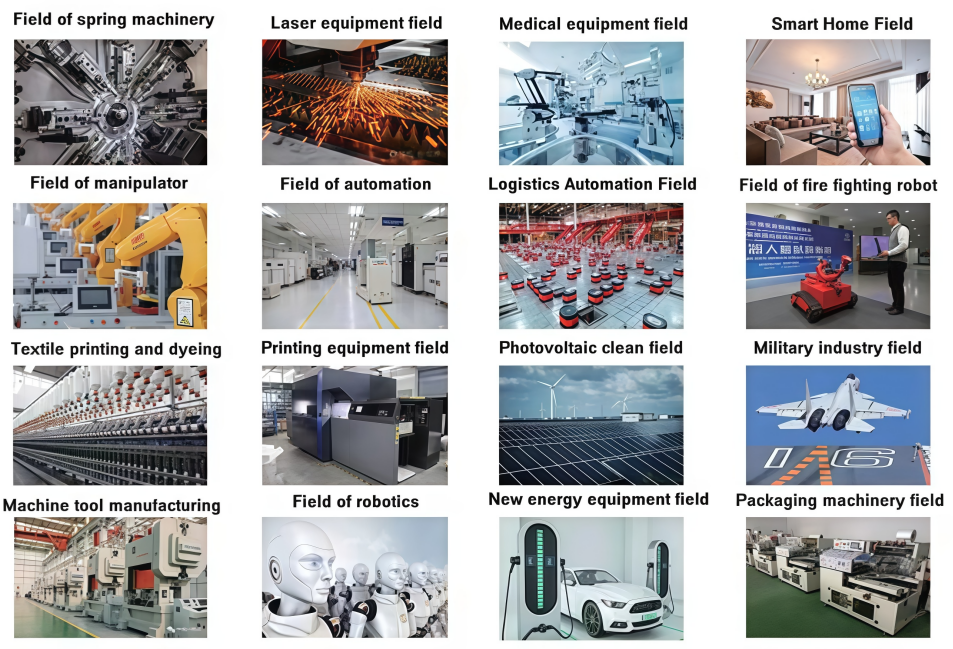

This product is widely used in the 3C battery manufacturing field, such as for smartphones, laptops, and tablets. Application scenarios include battery processing plants and electronic device assembly lines, improving cutting precision and consistency.

● High-Precision Cutting: Ensures consistent battery dimensions, reducing waste rate.

● Strong Durability: Made from premium materials, service life exceeds 500,000 cycles.

● Enhanced Efficiency: Suitable for high-speed automated production, shortens cycle time.

● Cost-Effective: Reduces maintenance and production costs.

● Customization Service: Design adjustments available based on customer requirements.

Q: What is a 3C Consumer Battery Cutting Mold?

A: It is a mold specifically designed for cutting batteries used in 3C devices, ensuring the battery shape and size meet standards.

Q: What is the maintenance cycle for the mold?

A: Routine inspection and cleaning are recommended every 100,000 production cycles to maintain optimal performance.

Q: Can the MOQ be adjusted?

A: Yes, it can be negotiated based on order volume.