Precision Molds & Parts: The Core Driving Force of High-End Manufacturing

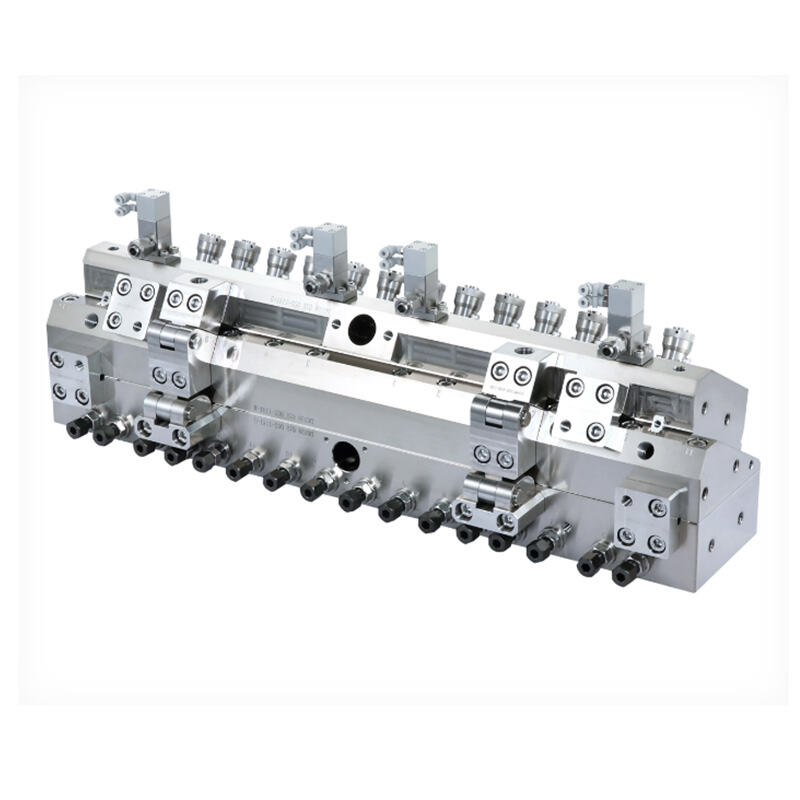

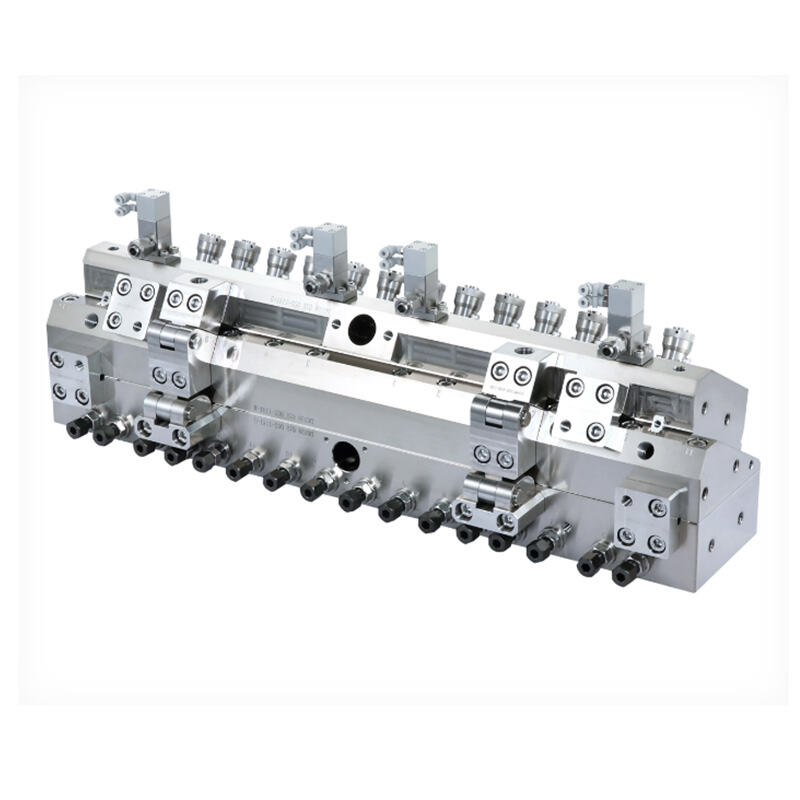

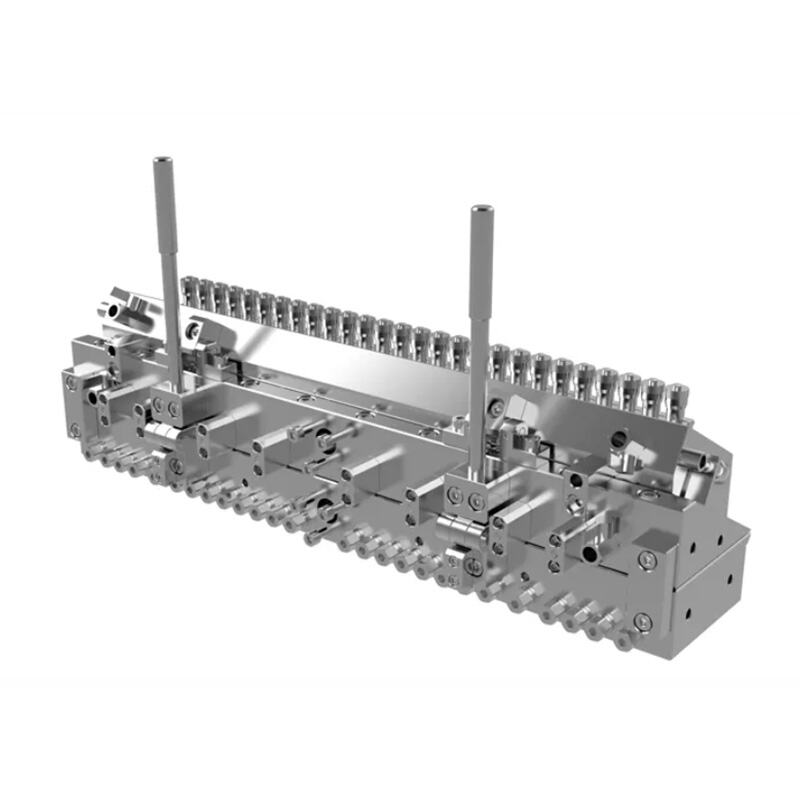

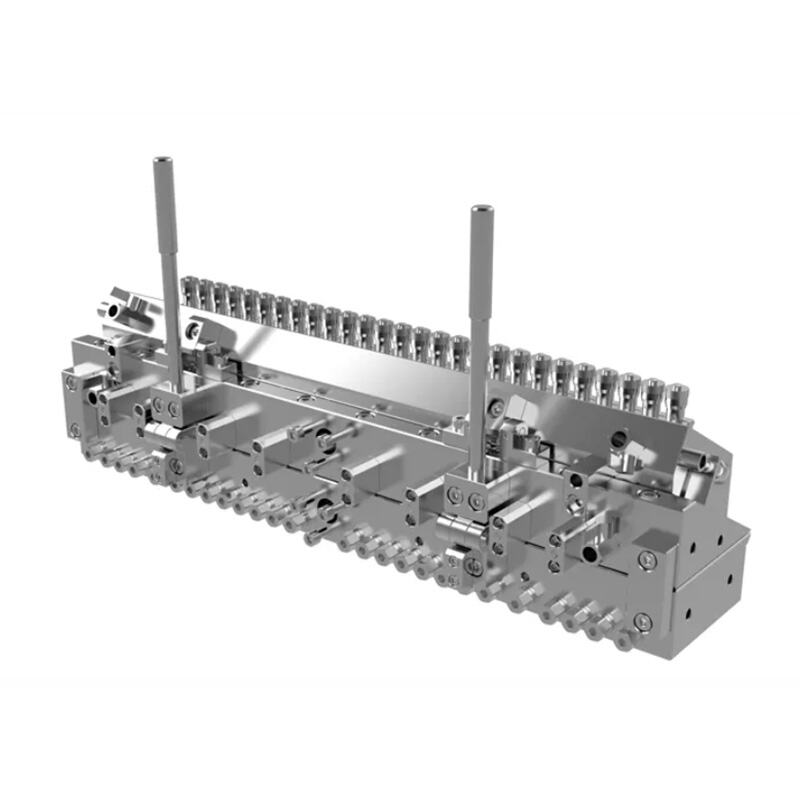

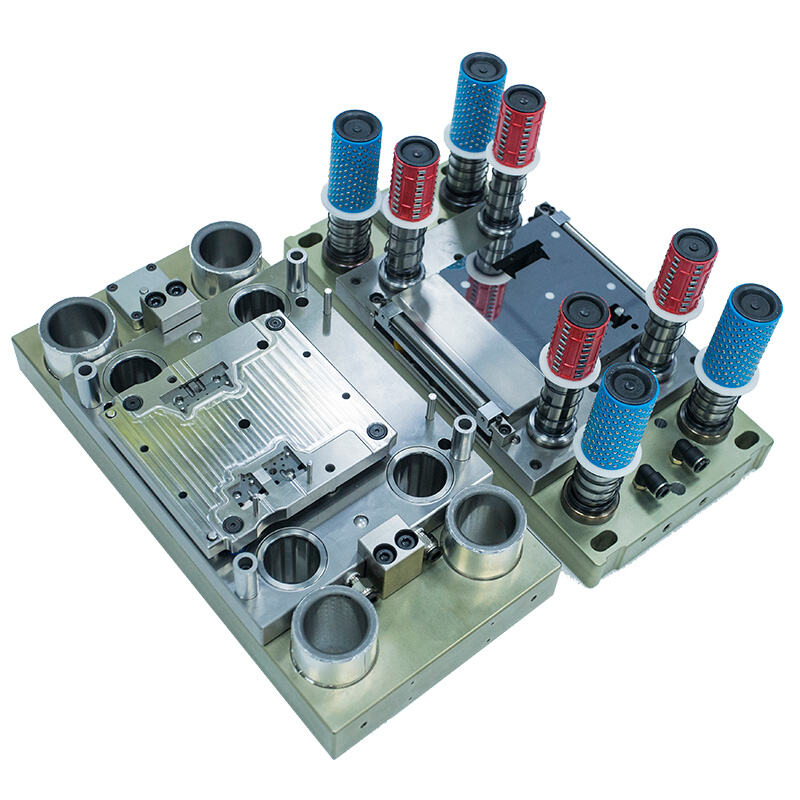

In the era of global manufacturing upgrading, precision molds and parts stand as the "cornerstone of industrial production" and the "core link of advanced manufacturing." As an indispensable part of modern industrial chains, Precision Molds & Parts refer to high-precision, high-stability mold tools and supporting components designed for mass production of complex workpieces, covering a wide range of processing technologies such as injection molding, stamping, die-casting, and machining. Their core value lies in realizing the precise replication of product structures, ensuring consistent quality of batch products, and laying the foundation for the efficiency, reliability, and innovation of downstream industries. From consumer electronics to automotive manufacturing, from medical devices to aerospace engineering, precision molds and parts are ubiquitous, becoming a key indicator of a country’s manufacturing strength and technological level.

The technical essence of Precision Molds & Parts lies in "ultra-high precision" and "high compatibility." In terms of dimensional accuracy, top-tier precision molds can achieve tolerances as low as ±0.001mm, which is equivalent to 1/100 of a human hair’s diameter. This level of precision is achieved through a combination of advanced processing equipment and strict quality control systems: CNC machining centers with five-axis linkage, electrical discharge machining (EDM) with micron-level positioning, and wire electrical discharge machining (WEDM) ensure the machining accuracy of mold cavities, cores, and components; while coordinate measuring machines (CMM), laser interferometers, and optical measuring instruments conduct full-process inspections to eliminate even the smallest deviations. In addition to dimensional precision, precision molds and parts also emphasize structural optimization—for example, the cooling system of injection molds is designed with bionic flow channels to ensure uniform cooling of plastic products, reducing warpage and shrinkage; the stamping die’s guide mechanism adopts high-hardness alloy materials and lubrication technology to improve wear resistance and extend service life. These technical details not only enhance the performance of the molds themselves but also directly determine the quality of final products, such as the flatness of smartphone casings, the sealing of automotive engine components, and the precision of medical catheters.

The application fields of Precision Molds & Parts are constantly expanding, penetrating into almost all high-value manufacturing industries. In the consumer electronics industry, precision injection molds are used to produce ultra-thin mobile phone shells, high-transparency screen protectors, and complex connector housings. With the popularity of 5G, IoT, and wearable devices, the demand for miniaturized, integrated precision parts is soaring—for example, the micro-molds for smart watch sensors require not only high precision but also compatibility with multiple materials such as plastic, metal, and ceramic. In the automotive industry, especially with the rise of new energy vehicles (NEVs), precision molds and parts play a crucial role in battery packs, electric motors, and electronic control systems. The stamping molds for battery cell casings need to withstand high-pressure forming processes while ensuring consistent thickness; the die-casting molds for motor housings require rapid heat dissipation and high surface finish to meet the requirements of lightweight and high efficiency. In the medical device industry, precision molds are used to produce disposable syringes, surgical instruments, and implantable devices. These products have extremely strict requirements for biocompatibility and dimensional stability—for example, the mold for medical catheters must ensure smooth inner walls to reduce tissue damage during insertion, and the tolerance must be controlled within ±0.005mm to ensure the accuracy of drug delivery.

Quality control is the lifeline of Precision Molds & Parts, and leading manufacturers adhere to international standards and establish a full-cycle quality management system. From raw material selection to finished product delivery, every link is subject to strict inspections: high-quality alloy steels (such as P20, H13), stainless steels, and engineering plastics are selected as base materials to ensure mechanical properties such as hardness, toughness, and corrosion resistance; heat treatment processes such as quenching, tempering, and nitriding are used to improve the wear resistance and service life of molds; in the assembly stage, technicians use precision tools to adjust the fit of components, ensuring smooth operation of the mold. Many enterprises have obtained certifications such as ISO 9001, IATF 16949 (automotive industry), and ISO 13485 (medical industry), which not only demonstrate their technical strength but also open the door to global markets. In addition, with the development of intelligent manufacturing, many manufacturers have introduced digital quality control systems, using big data and AI to analyze processing parameters and inspection results, realizing predictive maintenance of molds and continuous optimization of product quality.

The development of Precision Molds & Parts is closely linked to technological innovation, and emerging technologies such as 3D printing, digital twin, and AI are promoting its transformation and upgrading. 3D printing (additive manufacturing) has broken through the limitations of traditional machining, enabling the rapid prototyping of complex mold structures—for example, the lattice structure cooling channels produced by 3D printing can improve cooling efficiency by 30% compared with traditional channels, shortening the production cycle of plastic products. Digital twin technology establishes a virtual model of molds, simulating the entire process of injection molding, stamping, and die-casting in the digital world. This not only helps predict potential problems such as product defects and mold wear but also optimizes processing parameters without stopping production, greatly reducing R&D costs and time. AI technology is applied to mold maintenance and fault diagnosis—by analyzing the vibration, temperature, and pressure data during mold operation, AI algorithms can predict the remaining service life of molds and remind maintenance personnel to replace worn parts in advance, avoiding sudden production shutdowns. These technological innovations are constantly raising the technical threshold of the precision mold industry and promoting the transformation from "made in China" to "created in China."

In the global market, the demand for Precision Molds & Parts is growing steadily, driven by factors such as industrial upgrading, technological progress, and increasing consumer demand for high-quality products. According to market research reports, the global precision mold market size is expected to exceed $100 billion in the next five years, with Asia-Pacific as the fastest-growing region. China, as the world’s largest manufacturing country, has a huge demand for precision molds and parts, and domestic manufacturers are constantly narrowing the gap with international leaders in terms of technology and quality. Many enterprises have established R&D centers to invest in the research of new materials, new processes, and new structures, and actively expand overseas markets through technological innovation and brand building. At the same time, the government’s support for advanced manufacturing industries, such as policy subsidies and tax incentives, has also provided a favorable development environment for the precision mold industry.

In conclusion, Precision Molds & Parts are not only the basic tools of manufacturing but also the core driving force for industrial upgrading and technological innovation. With their ultra-high precision, high stability, and wide applicability, they support the development of downstream industries such as consumer electronics, automotive, and medical devices, and promote the transformation of global manufacturing towards high-quality, intelligent, and efficient directions. In the future, with the continuous integration of new technologies and the continuous expansion of application fields, Precision Molds & Parts will play a more important role in the global industrial chain, creating greater value for human society’s technological progress and economic development.

Copyright © 2025 by Delixi New Energy Technology (hangzhou) Co., Ltd. - Privacy policy