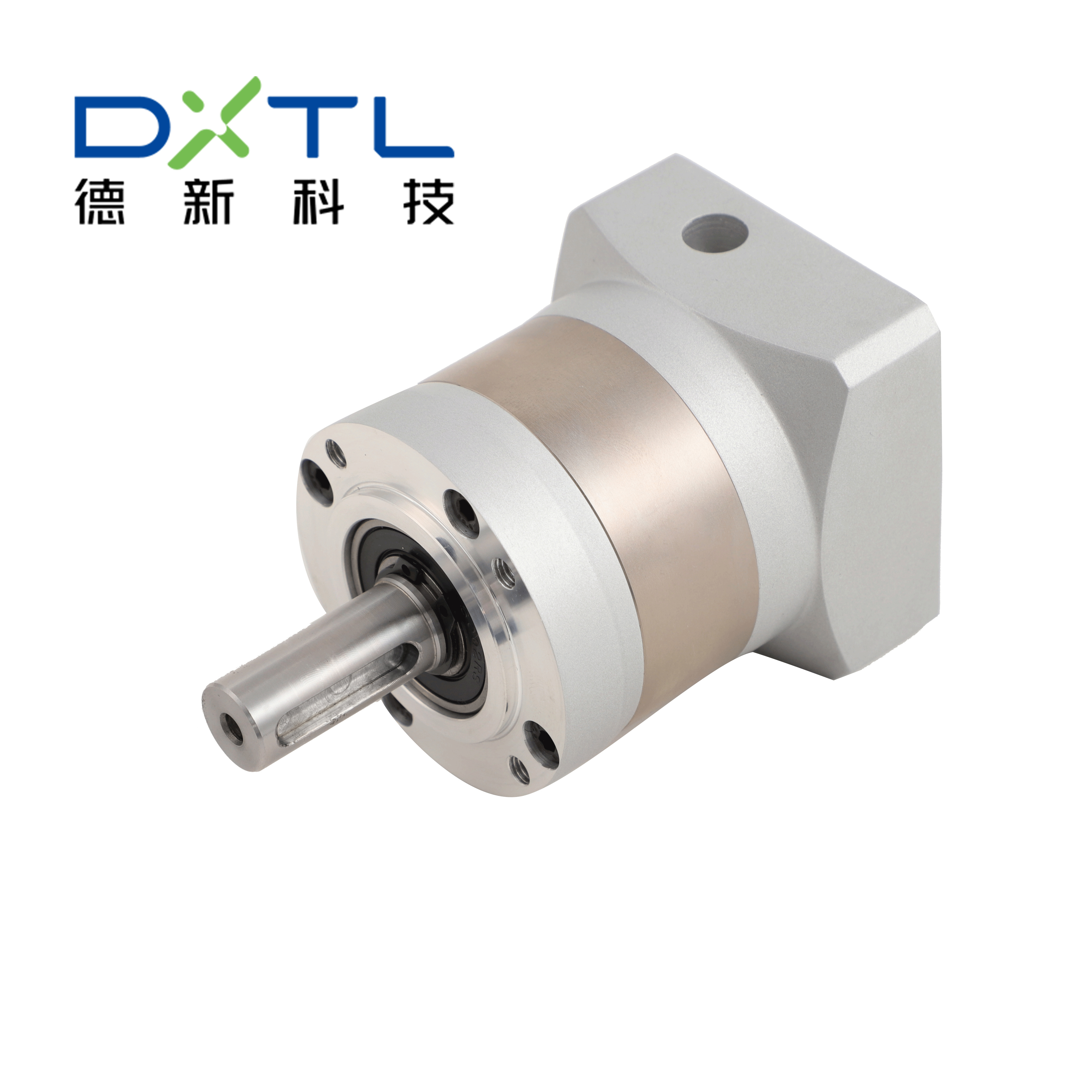

If you work with machines that use a planetary gearbox, you know how crucial this part is for smooth operation. A well-maintained planetary gearbox keeps your equipment running efficiently, saves you from costly repairs, and extends the overall lifespan of your machines. But many people aren’t sure where to start when it comes to maintaining a planetary gearbox. It doesn’t have to be complicated—just follow a few key steps, and you’ll keep your planetary gearbox in top shape. Let’s break down exactly what you need to do.

Check and Replace Lubricant Regularly

Lubricant is like the lifeblood of a planetary gearbox. It keeps the moving parts from rubbing against each other too much, reduces heat, and prevents wear and tear. First, you need to check the lubricant level in your planetary gearbox at least once a month—more often if the gearbox runs for long hours every day. To check, open the oil plug and see if the lubricant reaches the recommended level; if it’s too low, add the right type of lubricant (check your planetary gearbox manual for the correct kind). You also need to replace the lubricant entirely every 6 to 12 months, depending on usage. Old or dirty lubricant can clog the gearbox parts, so make sure to drain all the old oil before adding new ones. This simple step goes a long way in keeping your planetary gearbox working smoothly.

Inspect for Wear and Damage Often

Even with good lubrication, parts of a planetary gearbox can wear out over time. You should do a visual inspection of your planetary gearbox every couple of weeks. Look for signs like cracks on the gearbox housing, loose bolts, or unusual marks on the gears. If you notice any metal shavings in the lubricant when you check the oil level, that’s a red flag—it means some parts are wearing down and might need replacement. Also, listen to the planetary gearbox when it’s running. A healthy gearbox makes a steady, low noise; if you hear grinding, clicking, or squealing sounds, stop the machine right away and check for issues. Catching small damages early prevents them from turning into big, expensive problems for your planetary gearbox.

Keep the Planetary Gearbox Clean

Dirt, dust, and debris are enemies of a planetary gearbox. When these particles get inside, they can mix with the lubricant, scratch the gears, and block important parts. So you need to keep the outside of your planetary gearbox clean at all times. Wipe it down with a dry cloth every week to remove dust. If the gearbox is in a dirty environment (like a factory with lots of debris), use a soft brush to gently clean hard-to-reach areas. Also, make sure the seals and gaskets of the planetary gearbox are in good condition. Damaged seals let dirt in and lubricant out, so replace any seals that look cracked or worn. Keeping your planetary gearbox clean doesn’t take much time, but it protects it from unnecessary damage.

Monitor Operating Temperature

A planetary gearbox that gets too hot is a sign of trouble. Overheating can break down the lubricant faster, warp parts, and even cause the gearbox to fail completely. So you need to monitor the temperature of your planetary gearbox while it’s running. You can use a handheld temperature sensor to check the surface temperature—most planetary gearboxes should stay below 95 degrees Celsius. If it’s hotter than that, stop the machine and find out why. Common causes of overheating include low lubricant levels, dirty lubricant, or a misaligned gearbox. Fix the issue before turning the machine back on. Regular temperature checks help you spot problems early and keep your planetary gearbox from overheating.

Follow the Manufacturer’s Maintenance Schedule

Every planetary gearbox is a bit different, so the best way to maintain it is to follow the schedule provided by the manufacturer. The manual for your planetary gearbox will have specific guidelines—like when to replace parts, what lubricant to use, and how often to do certain checks. Don’t skip any steps in the schedule. For example, some planetary gearboxes need their bearings replaced every 2 to 3 years, even if they look fine. The manufacturer knows their product best, so their advice is the most reliable. If you lose the manual, you can contact the brand (like those from DXTLEX) to get a copy. Following the manufacturer’s schedule ensures you don’t miss any important maintenance steps for your planetary gearbox.

Maintaining a planetary gearbox isn’t about doing big, complicated tasks—it’s about being consistent with small, regular checks. By keeping the lubricant fresh, inspecting for damage, keeping it clean, monitoring temperature, and following the manufacturer’s advice, you’ll keep your planetary gearbox running well for years. This not only saves you money on repairs but also keeps your machines working without unexpected downtime.

Hot News

Hot News