Views: 0 Author: Site Editor Publish Time: 16-08-2025 Origin: Site

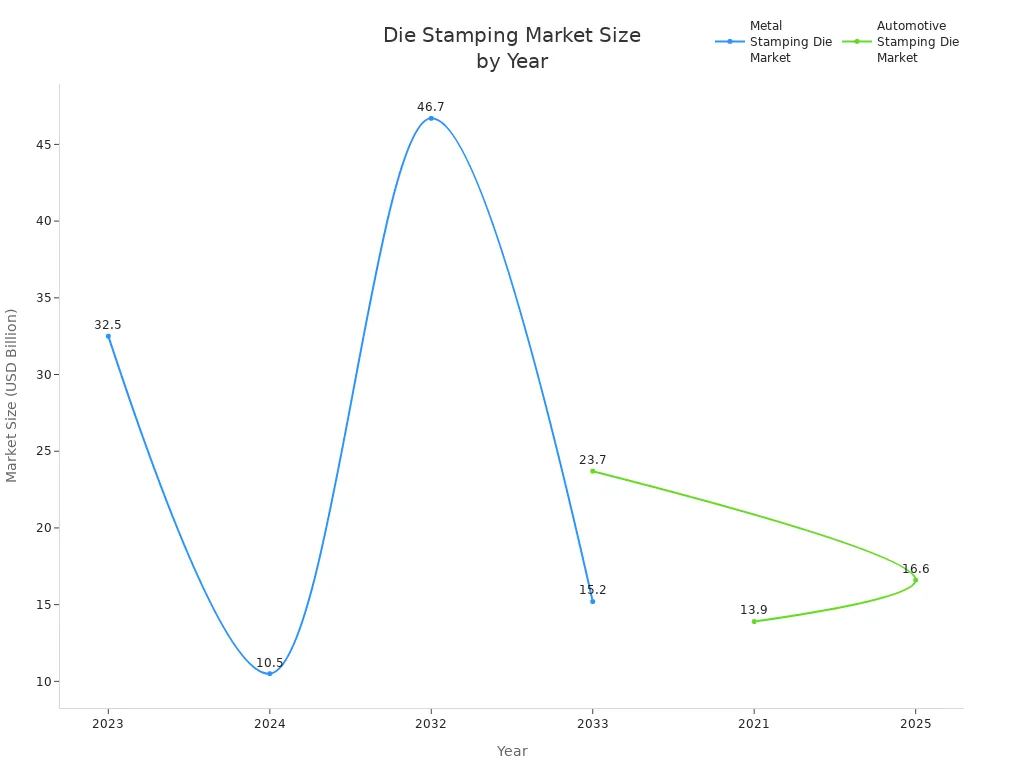

Die stamping changes flat metal by pressing it with a stamping die. People use this process to make exact parts for factories, like cars and electronics. A stamping die works like a special mold. It cuts and shapes metal very accurately. Knowing each step and how the die works helps you pick the best stamping process for your product. The world market for stamping die is still growing. It was $32.5 billion in 2023 and may reach $46.7 billion by 2032.

Stamping dies change flat metal into exact parts. They do this by cutting, bending, or shaping it with a press machine.

The stamping process has several steps. First, you prepare the metal. Next, you set up the die. Then, you feed the metal in. After that, you stamp it. Finally, you remove the finished parts with care.

There are different die types. These include progressive, compound, transfer, and single punch. Each type works for different amounts and kinds of parts.

Picking the right die depends on the part’s shape and how many you need. It also depends on your budget and how exact the part must be. This helps save time and money.

Keeping dies in good shape and designing them well is important. This makes sure stamping dies stay accurate and last long. It also helps make good parts quickly.

A stamping die is a special tool that helps you shape flat metal into useful parts. You use it in a press machine to cut, bend, or form metal sheets. The die acts like a mold, giving each piece the exact shape you need. You find stamping dies in many industries, such as automotive, electronics, and appliances. When you want to make many parts that look the same, you rely on a stamping die for accuracy and speed.

A stamping die has several important jobs. It must cut metal, form it, and sometimes punch holes or make bends. You can think of it as a stamping tool that works with high force to change the metal’s shape. Each die is made for a specific part, so you get the right size and features every time.

You can see the main components and their functions in the table below:

| Component Category | Main Function |

|---|---|

| Working Components | Perform stamping operations such as cutting, piercing, forming, and bending on sheet metal. |

| Pilot Components | Control raw material feeding direction and position to ensure correct alignment in the die. |

| Guide Components | Ensure precise alignment and movement between upper and lower die parts for quality stamping. |

| Stripping and Lifting Components | Remove stamped parts and scrap material after each operation to prepare for the next cycle. |

| Fastening Components | Secure all die parts together and fix the die onto the press machine for stable operation. |

| Additional Components (for high volume) | Include automatic feeding and ejection devices to improve efficiency and tooling life. |

Tip: When you choose a stamping die, always check if it matches your part’s shape and production needs.

You use a stamping die inside a press machine to shape metal. The process starts when you feed a metal strip or blank into the press. The die then presses down with great force. This force cuts, bends, or forms the metal into the shape you want. Each time the press cycles, the die repeats the same action, so every part comes out the same.

Here is a simple step-by-step look at how a stamping die works:

You feed a metal strip or blank into the press.

The die applies force to the metal, cutting or forming it.

In progressive stamping, the metal moves through several stations, each doing a different job.

Transfer dies move the part from one station to another automatically.

Line dies may need you or a machine to move the part between stations.

The die can perform many actions, such as blanking, piercing, bending, or drawing.

The press and die work together to shape the metal with high precision.

You can find these steps in many factories, especially where you need to make thousands of parts quickly. The stamping die ensures each part has the correct shape, size, and features.

Note: Stamping dies use cold-forming, which means you do not need to heat the metal before shaping it. This saves energy and keeps the process fast.

You need strong materials to build a stamping die. Most dies use hardened tool steel or carbide. These materials resist wear and keep their shape even after thousands of cycles. Tool steel is common because it balances cost, toughness, and wear resistance. Carbide is even harder and lasts longer, but it costs more.

Here is a table showing common die materials and their properties:

| Material Type | Mechanical Properties and Characteristics |

|---|---|

| Carbon Tool Steel | Good processing, low cost, but lower hardenability and strength. Prone to deformation under heat. |

| Low-Alloy Tool Steel | Better hardenability and wear resistance than carbon steel. Less likely to crack or deform. |

| High-Speed Steel | Very hard and wear-resistant. Handles high loads. Needs special forging for best results. |

| High-Carbon Medium-Chromium Tool Steel | Good stability and hardenability. Less deformation during heat treatment. |

| High-Carbon High-Chromium Tool Steel | High wear resistance and stability. Needs special forging to avoid carbide segregation. |

| Cemented Carbide | Extremely hard and wear-resistant. Lower toughness, so best for high-wear, low-impact jobs. |

You also need to design the die carefully. Engineers use computer-aided design (CAD) to create precise models. CAD lets you see the die before making it, so you can fix problems early. You can also use simulation tools to test how the die will work under pressure. This helps you avoid mistakes and makes the die last longer.

To make a stamping die last, you must:

Pick materials with the right hardness and toughness.

Use heat treatments like quenching and tempering to make the die stronger.

Design the die to spread out stress and avoid cracks.

Use coatings to reduce friction and wear.

Keep the die clean and well-oiled for smooth operation.

Tip: Regular maintenance keeps your stamping die in top shape and helps you avoid costly downtime.

A well-designed stamping die gives you high precision and long life. You get parts with the exact shape you need, every time.

The sheet metal stamping process changes raw metal into exact parts with a stamping die. You follow certain steps to make sure every part is good quality. Each step is important for the final part. Here is how you go from raw metal to finished product in metal stamping.

You begin by getting the metal ready. First, you pick metal sheets or coils. You choose based on strength, how easy it bends, if it resists rust, how well it carries electricity, and the price. The choice depends on what the part will do. For example, cars often use steel because it is strong. Electronics may use copper because it carries electricity well.

Before you start, you need to know the metal’s mechanical properties. This helps you see if the metal can handle stamping. If you skip this, you might break the die or make bad parts.

Next, you cut, slit, and flatten the metal to the right size. This makes sure the metal fits the die and moves smoothly into the press. You also check that the blanks are flat and the same thickness. If they are not, you can get defects during stamping.

Quality control is very important here. You might clean and oil the blanks before stamping. Oil helps stop friction and keeps the metal and die safe. These steps help you avoid problems and make better parts.

Tip: Always check the metal’s thickness and surface first. Good preparation stops costly mistakes later.

After you get the material ready, you set up the die. You start by looking at the part’s shape, the metal type, and how thick it is. You also check what size changes are allowed. This helps you plan the stamping steps and make a strip layout. The layout shows how the metal moves through the die and where each job happens.

You look for problems like tearing or wrinkling. You can use computer tests or ask experts to find issues before making the die. This saves time and money by stopping mistakes.

Next, you pick a press machine that matches the die’s force and height. You clean the press and the bottom of the lower die seat. This cleaning removes dirt and makes the setup flat and steady.

You then put the die in the center of the press table. This makes sure the force is even during stamping. You set the press to move slowly for better control. You line up the die parts, clamp the upper die, and do a few empty runs. These steps check that everything works well. For special dies, like V-shaped ones, you adjust the slider for the metal’s thickness.

Good die setup makes stamping better, helps the die last longer, and makes work faster.

After setting up the die, you feed the metal into the press. There are different ways to feed the metal, depending on what you need.

The most common way is continuous feed coil stamping. Here, you feed metal from a coil through many stations in the die. Each station does a different job, like cutting or bending. This way works well for progressive stamping and lets you make many parts fast.

You can also use roll feeds or gripper feeds. Roll feeds use rollers to move the metal. They can be run by the press, by themselves, or by a servo. Servo feeds give you more control and can handle different lengths. Gripper feeds use clamps to move the metal. They are good for short lengths and can be programmed.

| Feeding Method | Description | Power Source Variations | Key Characteristics |

|---|---|---|---|

| Roll Feeds | Use rollers to move sheet metal into the tool | Press-driven, Self-powered (air/hydraulic), Servo-driven | Synchronized with press or programmable; unlimited feed length possible |

| Gripper Feeds | Use clamps and linear motion to move the strip | Self-powered, Servo-driven, Press-driven | Limited feed length; programmable; good for automation |

Automation has made feeding metal easier and faster. Automated lines use machines to unroll, straighten, and control the metal. These systems keep the metal flat and feed it at the right speed. Automation cuts down on hand work, lowers mistakes, and makes things safer. Smart sensors and cameras help watch the process and find problems early.

Note: Automated feeding makes production faster and helps make better parts by keeping the metal in the right place.

With the metal ready, you start the stamping operation. The stamping die closes around the metal, and the press pushes down. This force shapes, cuts, or forms the metal into the part you want. Stamping uses cold-forming, so you work at room temperature. You do not need to heat the metal, which saves energy and time.

Stamping can do many things, like blanking, piercing, bending, forming, or drawing. Each job happens at a different station in the die. In progressive dies, the metal moves from one station to the next. Each station does a special job. In transfer dies, the part moves by itself between stations.

| Aspect | Cold-Forming (Cold Stamping) | Hot-Forming (Hot Stamping) |

|---|---|---|

| Temperature | At or near room temperature | Steel heated to ~900 °C before forming |

| Equipment | Uses standard presses (630-2500 tons) | Needs high-tonnage presses and large furnaces |

| Process Complexity | Simpler, lower tonnage, mechanical blanking and trimming | More complex, involves heating, forming, quenching, and laser trimming |

| Material Range | Wide variety of metals | Mostly press-hardened steels |

| Energy Requirements | Lower | Higher due to heating and quenching |

You must watch the stamping process closely. Change the pressure, speed, or alignment if you see problems like cracks or wrinkles. Oil during stamping helps the die last longer and makes better parts.

Tip: Cold-forming in sheet metal stamping gives you very exact and repeatable parts. This is great for making lots of parts.

After stamping, you need to take the finished part out of the die. Good part removal keeps things moving and stops damage to the die or part.

There are many ways to remove parts:

| Technique | Description | Key Advantages / Notes |

|---|---|---|

| Air-Blast Systems | Use bursts of air to blow parts and scrap from under the die. | Simple, but can be noisy; needs coordination with press controls. |

| Air Shakers and Transporters | Shake trays to move parts forward, like a tablecloth effect. | Good for small presses; needs balanced trays and regular maintenance. |

| Belt Conveyors | Move parts from the press to collection boxes. | Adaptable; works for large, uniform parts; risk of carryover. |

| Steel Hinge Belt Conveyors | Use steel plates and hinges to move heavy scrap or parts. | Durable; good for heavy loads; stationary due to weight. |

| Vibratory Trough Conveyors | Vibrate trays to move parts horizontally. | No belts to damage; keeps area clean; can be noisy. |

| Shuffle Drive Tray Systems | Heavy-duty trays move parts using a tablecloth-like motion. | Good for large presses; effective for scrap removal. |

Automation helps here too. Robots and smart conveyors can take out parts fast and safely. This means less hand work and fewer injuries or mistakes.

Note: Good part removal keeps your stamping die safe and your production line running well.

By following these steps, you make sure your sheet metal stamping works well. Every step, from getting the metal ready to taking out the part, affects the quality and cost of your product. Knowing the whole stamping process helps you make better choices and get the best results in metal stamping.

Sheet metal stamping uses a few main steps to change flat metal into finished parts. Each step has its own job. Some steps shape the metal. Others cut or form it. You need to know these steps to pick the right die and process for your project.

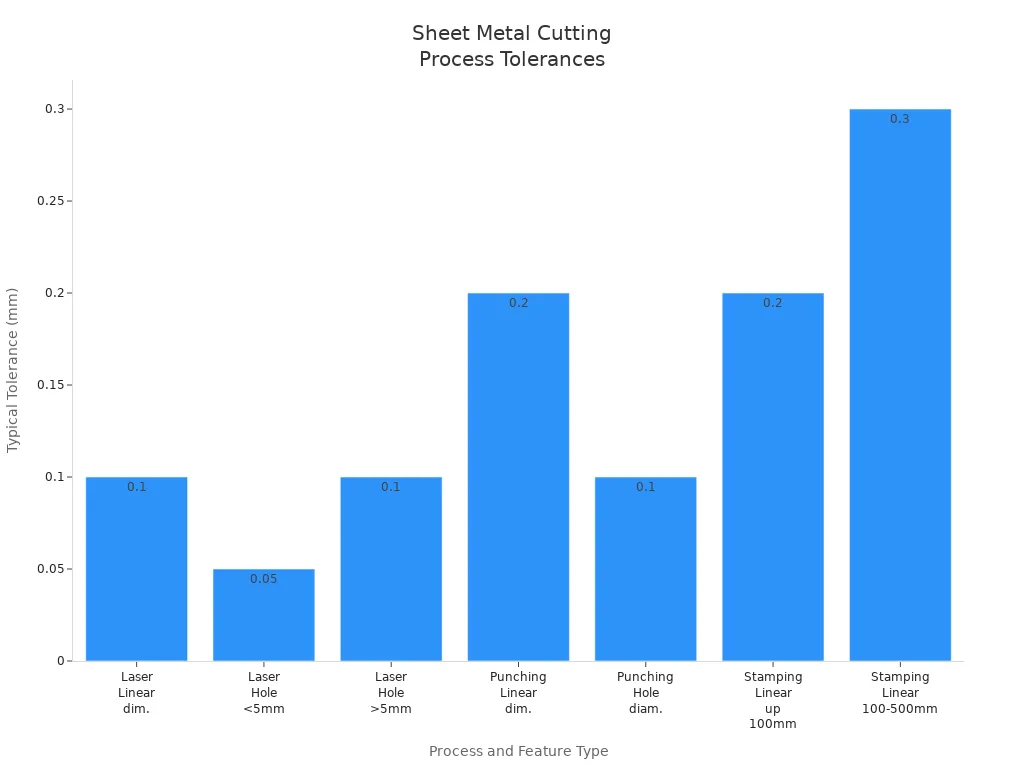

Cutting is often the first step in stamping. You use a die to cut metal into shapes or strips. Laser cutting and CNC punching are common ways to do this. Laser cutting is very exact and works for tricky shapes. CNC punching is fast and good for making holes. The table below shows how close the cuts can be for each method:

| Process | Feature Type | Typical Tolerance |

|---|---|---|

| Laser Cutting | Linear dimensions | ±0.1 mm (up to 1000 mm) |

| Hole diameter < 5 mm | ±0.05 mm | |

| Hole diameter > 5 mm | ±0.1 mm | |

| Punching | Linear dimensions | ±0.2 mm (up to 1000 mm) |

| Hole diameter | ±0.1 mm | |

| Stamping | Linear dimensions | ±0.2 mm (up to 100 mm) |

| ±0.3 mm (100-500 mm) |

You can see that different methods have different tolerances. Laser cutting is best for small, detailed parts.

Blanking is a cutting step where you take out a piece from the metal sheet. The piece you cut out is the part you want. The rest of the sheet is scrap. You use blanking to make many small parts from one big sheet. This helps you get the right shape for the next steps.

| Aspect | Blanking | Piercing |

|---|---|---|

| Process | Cutting operation where the removed piece is the desired workpiece | Shearing process to create holes in sheet metal; the punched-out piece is scrap |

| End Result | Produces multiple small metal parts from a single sheet | Creates holes in the metal sheet; the sheet with holes is the workpiece |

| Scrap | Remaining sheet metal is scrap | Punched-out metal is scrap |

| Purpose | To obtain the cut-out piece as the final product | To create holes in the sheet metal |

Piercing makes holes or cut-outs in the metal sheet. You use a die to punch through the metal. The part with the holes is your workpiece. The bits you punch out are scrap. Piercing usually comes after blanking. In car factories, you use piercing to make holes in body panels and engine parts. In electronics, you make openings for switches and connectors.

Automotive: You make holes in car panels and shape engine parts.

Electronics: You make small openings for switches and connectors.

Forming bends or shapes the metal without cutting it. You use a die to press the metal into a new shape. Bending folds the metal in a straight line. Stretching pulls the metal to make curves. Four-slide stamping lets you bend from different sides. Forming changes the shape of your part and helps you get the right angles.

Drawing pulls the metal into a three-dimensional shape. You put a flat blank over a die and press it with a punch. A blank holder keeps the metal in place. Sometimes you need more than one drawing step to get the final shape. Drawing makes deep, hollow parts like cans and airbag inflators. This gives you strong parts with no seams.

You design the part and pick the right die and punch.

You choose the best metal, like aluminum or steel.

You put the blank on the die and press it with the punch.

You repeat the steps to get the final shape.

You use drawing for things like airbag inflators and leak-proof containers.

Coining uses a lot of pressure to press the metal into the die. This step gives you a smooth surface and exact shapes. Coining needs more force than other steps. You use it when you want fine details or need to control the part’s thickness. Coining can make raised or sunken designs with little springback.

| Stamping Operation | Pressure Requirement | Surface Finish and Precision |

|---|---|---|

| Coining | Very high (5-10 times more than air bending) | Produces very fine, detailed surface finish with minimal springback; exact replication of die shape |

| Air Bending | Low | Less detailed surface finish; prone to springback |

| Embossing | Lower than coining | Raised or recessed designs; less intricate detail |

Tip: Keeping your die clean and in good shape helps your stamping stay accurate and last longer.

When you choose a metal stamping die, you need to know the main types of stamping dies. Each die works in a different way and fits certain jobs. You can pick the best die for your project by learning how each one works.

A progressive die lets you make parts fast and with high accuracy. You feed a metal strip into the die. The strip moves through several stations. Each station does a job like cutting, bending, or punching. The die finishes the part as the strip moves forward. You get a finished part with every press stroke.

You use progressive dies for high-volume jobs.

The process is highly automated and reduces labor.

You get tight tolerances and consistent quality.

Progressive dies work well for automotive, electronics, aerospace, and consumer goods.

You can make complex parts, but the die design must be exact.

The initial tooling cost is high, but you save money on large runs.

Progressive dies are not ideal for small batches or very deep parts.

Tip: If you need millions of parts with the same shape, a progressive die gives you speed and repeatability.

A compound die does several jobs in one press stroke. You can cut inside and outside shapes at the same time. This die keeps the part flat and accurate. You use compound dies when you need more than a simple blanking die but do not want the cost of a progressive die.

Compound dies work best for medium runs.

You get high precision and flatness.

The die is more complex and costs more than a single die.

You use compound dies for parts with many holes or shapes that need to be made at once.

| Aspect | Compound Die Details |

|---|---|

| Operation | Multiple features in one stroke |

| Best for | Medium to high volume, high precision parts |

| Part Flatness | Excellent |

| Die Complexity | High |

A transfer die uses separate stations for each step. You cut the part from the strip at the start. Special equipment moves the part from one die to the next. You use transfer dies for large or complex parts that need many forming steps.

| Aspect | Transfer Die | Progressive Die |

|---|---|---|

| Material Handling | Parts moved by transfer equipment | Strip moves through die stations |

| Part Size/Complexity | Large, complex parts | Small, less complex parts |

| Speed | Slower | Faster |

| Equipment | More complex | Simpler |

You pick a transfer die when you need to form deep or large shapes that a progressive die cannot handle.

A single punch die does one job at a time. You use it for simple parts or low-volume runs. You place the metal in the die, press once, and remove the part. This die is easy to set up and costs less than other types.

Best for prototypes or small batches.

Simple design and easy maintenance.

Not good for complex shapes or high-speed production.

Note: You can choose from many types of dies. Think about your part’s shape, how many you need, and your budget before you decide.

It is important to know what each die does well and what it does not. Every die type works best for certain jobs. Each one also has limits. The table below shows the main good and bad points:

| Die Type | Advantages | Disadvantages |

|---|---|---|

| Single Punch Die | Simple design, low cost, easy to adjust | Slow production, low material use, not good for automation |

| Progressive Die | Fast, highly automated, less waste, great for complex shapes | High setup and maintenance cost, hard to change design, big investment needed |

| Compound Die | Good for medium batches, high precision, economical | Not for mass production, hard to remove material |

| Transfer Die | Handles complex parts, high automation, low waste | High cost, needs big equipment, hard to maintain, not for small batches |

You pick a progressive die when you want to make lots of parts fast. It is good if you need very exact sizes. A compound die is best for simple shapes and medium amounts. Transfer dies help you make big or deep parts that need many steps. Single punch dies are good for small jobs or if you change the part often.

Tip: Always choose a die that fits your needs and budget.

Different dies are used for different jobs and industries. The table below shows where each die works best:

| Die Type | Typical Operations | Common Industries |

|---|---|---|

| Single Punch Die | Blanking, piercing, bending, drawing | Automotive, appliances, small batches |

| Progressive Die | Multiple steps in one cycle | Automotive, aerospace, electronics |

| Compound Die | Cutting and punching at once | Electronics, medical equipment |

| Transfer Die | Moving parts between stations | Automotive (body panels), large parts |

Progressive dies are common in car factories. They make body panels and brackets. Electronics companies use compound dies for small, exact parts. Transfer dies help shape big parts for cars and trucks. Single punch dies are good for test parts or small runs.

Think about a few things before you choose a die:

Look at your part’s shape and how hard it is to make. Hard shapes may need a progressive die or transfer die.

Check how many parts you want to make. If you need a lot, use a progressive die. For small amounts, use a single punch die.

Think about your budget. Progressive dies cost more at first but save money if you make many parts.

See how easy it is to change the die. If you change designs a lot, pick a single punch die.

Make sure your die fits your press machine and space.

Always check the quality you need. If you need very exact sizes, you may need a progressive die.

Note: Planning ahead helps you pick the right die and saves money.

You now know that stamping dies help shape metal parts for many uses. Picking the right die for your job makes your products better and saves money. Stamping lets you do many steps at once, so you waste less metal and work faster. Car makers, electronics companies, and others use stamping dies a lot. The table below shows what matters most:

| Key Factor | Impact on Stamping Die Choice |

|---|---|

| Cost | Lower per-part cost for high volumes |

| Part Volume | Stamping suits large batches |

| Geometry & Features | Complex shapes need stamping dies |

Progressive stamping dies help you save time and work.

Using machines and smart die design gives you good results.

Planning for bigger jobs makes your factory run better.

Remember to use these ideas when you pick a stamping die for your next project.

A Stamping Die is a tool that shapes or cuts metal sheets. You use it to make parts for cars, electronics, and appliances. It gives you accurate, repeatable results. You need it for high-volume production and precise shapes.

In compound die stamping, you use a single press stroke to cut and shape metal at the same time. This process lets you make flat, detailed parts quickly. You get high accuracy and save time compared to using separate dies.

A stamp and die set includes punches, die plates, guide pins, and springs. You also find stripper plates and fasteners. Each part helps you cut, form, or guide the metal. Good stamping die components improve part quality and tool life.

You clean your stamping die after each use. You check for wear or cracks. You oil moving parts and store the die in a dry place. Regular stamping die maintenance helps you avoid breakdowns and keeps your metal stamping die sets working well.

You use automotive stamping dies to make car body panels, brackets, and engine parts. These dies help you produce strong, lightweight parts in large numbers. Automotive stamping die tools are key for fast, accurate car manufacturing.

Home | About Us | Molds | Precision Automation | Spare Parts | Solutions | Support | News | Contact Us