Inspect lubrication system regularly for speed reducers

The lubrication system is the lifeline of speed reducers, and regular inspection ensures it functions properly to reduce friction and wear. Start by checking the lubricant level using the speed reducers’ sight glass or dipstick—ensure it’s within the recommended range, not too high or too low. Next, observe the lubricant’s condition: fresh lubricant should be clear and free of impurities, while discolored (dark brown or black), cloudy, or particle-filled lubricant indicates contamination or degradation. Use a clean cloth to wipe the oil drain plug and check for metal shavings—this signals internal component wear. Also, inspect lubricant lines, seals, and gaskets for leaks; even small leaks can lead to insufficient lubrication. Follow the manufacturer’s guidelines to replace lubricant at specified intervals, and use the correct type and viscosity. A well-maintained lubrication system keeps speed reducers running smoothly and prevents premature failure.

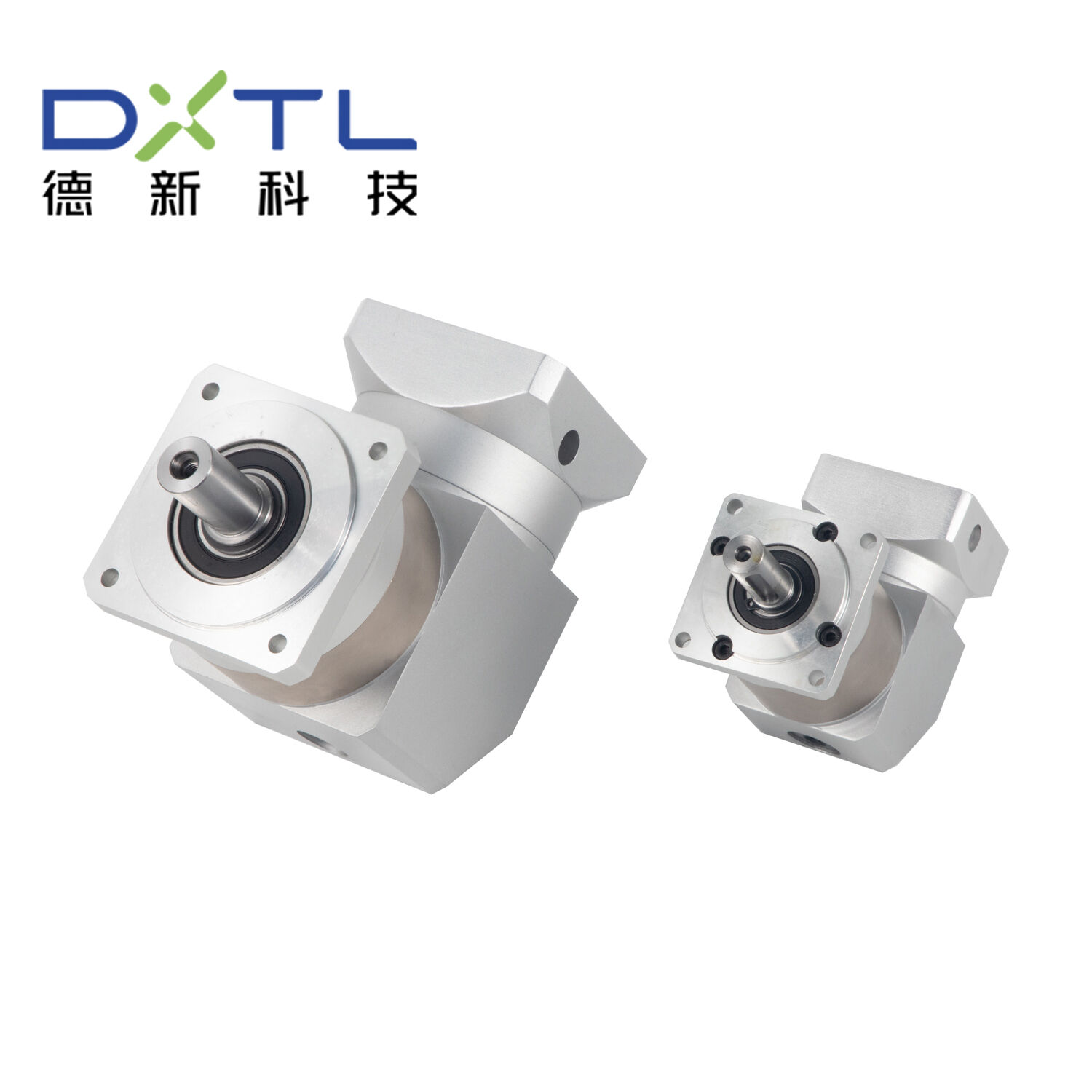

Check mechanical components for wear and damage

Speed reducers rely on precise mechanical components like gears, bearings, shafts, and couplings—regular inspection catches wear or damage early. Examine gear teeth for signs of pitting, chipping, uneven wear, or backlash (excessive play between meshing gears). Rotate the input and output shafts by hand to feel for roughness, resistance, or loose bearings—smooth rotation without noise indicates healthy bearings. Inspect shafts for bending, corrosion, or damage to keyways (the slots that connect shafts to other parts). Check couplings (flexible or rigid) for cracks, wear, or loose fasteners, as misaligned or damaged couplings cause vibration and stress. For bolted connections (mounting bolts, cover bolts), ensure they’re tight—loose bolts lead to vibration and component damage. Early detection of worn parts allows for timely repair or replacement, avoiding costly breakdowns and extending the speed reducers’ service life.

Verify alignment and mounting stability of speed reducers

Proper alignment and stable mounting are critical for speed reducers’ long-term operation, and regular checks prevent misalignment-related issues. Use a straightedge or laser alignment tool to verify that the speed reducers, motor, and driven equipment are correctly aligned—both angularly (shafts parallel) and radially (no offset). Misalignment causes uneven wear on gears and bearings, increased vibration, and noise. Adjust mounting feet or shims if alignment is off, even by a small margin. Inspect the mounting surface for stability: ensure the base is level, rigid, and free of cracks. Check vibration-damping pads (if used) for deterioration—worn pads fail to absorb shocks, transferring vibration to the speed reducers. Tighten all mounting bolts and fasteners, as vibrations during operation can loosen them over time. Maintaining proper alignment and stable mounting reduces stress on internal components, prolonging the speed reducers’ lifespan.

Monitor operating parameters of speed reducers

Tracking key operating parameters helps identify abnormal conditions that could shorten speed reducers’ service life. Use a temperature gauge to monitor the speed reducers’ housing temperature—excessive heat (above manufacturer’s limits) indicates issues like insufficient lubrication, overloading, or blocked vents. Listen for unusual noises (grinding, whining, rattling) during operation, which signal component wear or misalignment. Measure vibration levels with a handheld vibration meter—consistently high vibration points to unbalanced parts, loose connections, or bearing damage. Record operating hours to schedule maintenance tasks (lubricant changes, component inspections) accurately. For critical applications, install sensors to monitor temperature, vibration, and lubricant condition in real time. By keeping a close eye on these parameters, you can address minor issues before they escalate into major failures, ensuring speed reducers operate reliably for longer.

Implement a systematic regular inspection schedule

A structured inspection schedule ensures no aspect of speed reducers’ maintenance is overlooked. Create a checklist tailored to your speed reducers’ model and operating conditions, including daily, weekly, monthly, and annual tasks. Daily checks: visually inspect for leaks, listen for abnormal noises, and confirm lubricant level. Weekly checks: tighten loose fasteners, clean vents and cooling fins, and check for signs of overheating. Monthly checks: analyze lubricant condition, measure vibration and temperature, and inspect seals for wear. Annual checks: perform a full disassembly (if needed) to inspect internal components, replace worn parts, re-align shafts, and update lubrication systems. Keep detailed inspection records, noting findings, repairs, and replacements. Train operators to perform basic inspections and report issues promptly. A systematic approach to regular inspection ensures speed reducers are always in optimal condition, maximizing their service life and minimizing downtime.

Hot News

Hot News