When components aren't perfectly aligned, it creates a chain reaction of positioning problems across planetary reducer systems. Even tiny angular shifts matter a lot here. A mere 0.05 degree misalignment at the start can balloon into over 0.25 degrees of error by the third reduction stage, basically multiplying the original mistake five times over due to how the gears interact. What happens is pretty straightforward mechanically speaking. Misaligned sun gears push planets into off-center rotations, which messes up how teeth engage properly. These transmission errors show up as speed variations that go beyond 2% in really precise applications, making it tough to get consistent positioning in robotic arms and CNC machines. Heat makes things worse too. When temps rise past 40 degrees Celsius in industrial settings, about 78% of all accuracy losses come from components shifting out of their proper positions. That's what tribology experts found in their studies on machine mechanisms.

The way gears align affects how much backlash builds up and how the load gets spread throughout planetary gear sets. When carriers are properly positioned, they keep consistent space between each planet gear and the ring gear. This helps keep backlash under that important 5 arc-minute limit needed for good motion control work. Strain gauges show something interesting too: aligned systems only have around 7% difference in load between planets. But when things aren't aligned right, we see differences jumping above 35%. These kinds of imbalances put extra pressure on certain gear teeth, which leads to faster wear problems like pitting and spalling. Getting alignment right matters most when changing directions because that's when proper backlash control becomes absolutely essential. According to ISO/TC 60 tribology standards, about 62% of early reducer failures come from impact damage caused by uncontrolled backlash during these directional changes.

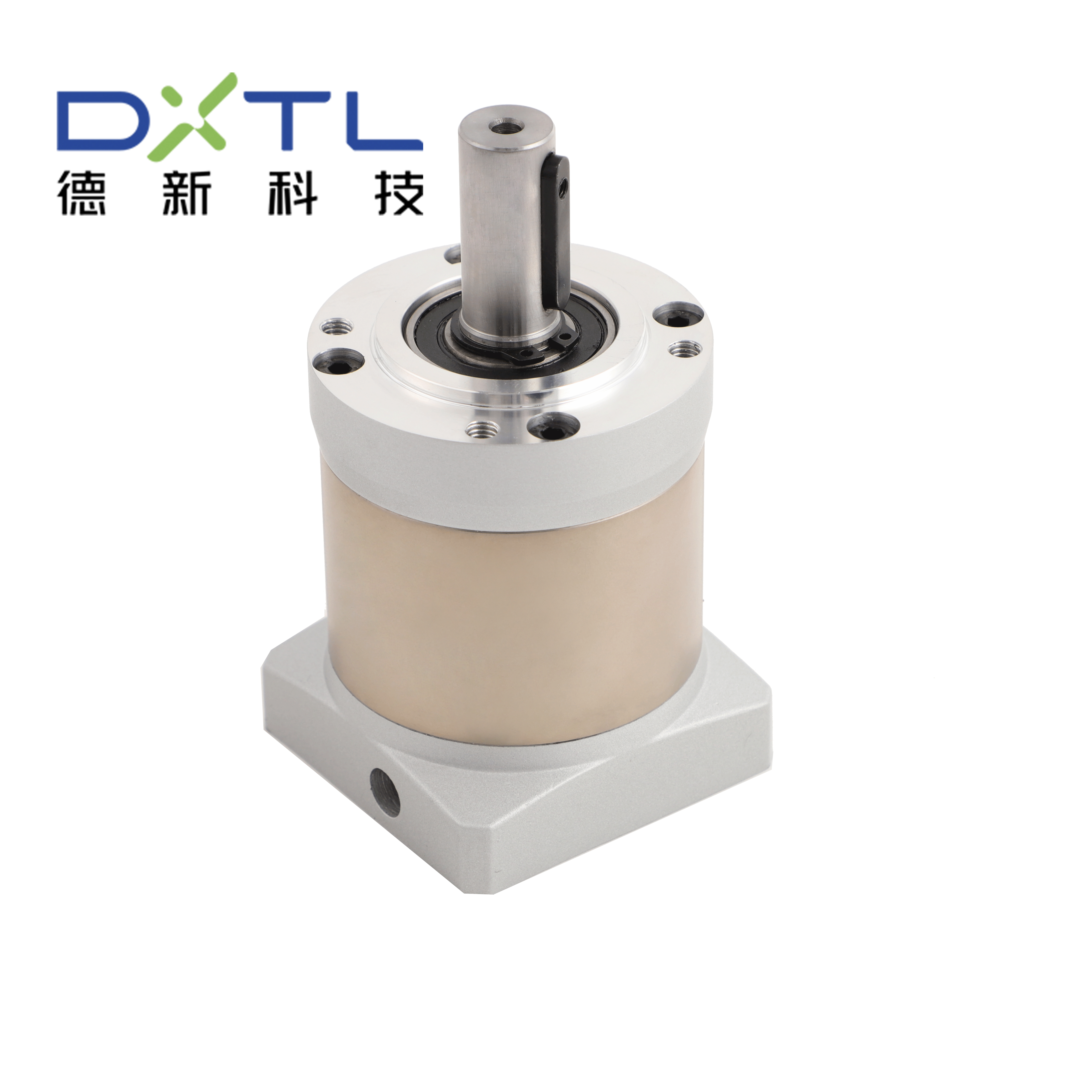

The planetary carrier acts as the main structural backbone for maintaining gear train stability. What makes it special is how it does much more than just hold things together. It actually keeps those sun, planet, and ring gears properly aligned even when subjected to all sorts of operational forces and vibrations. Forged alloy versions really stand out in this regard. These forged parts have better grain structure continuity than their cast counterparts, which gives them a distinct edge in resisting deformation from heavy loads and temperature changes during operation. This matters a lot in real world applications where reliability under stress is absolutely essential.

When gearboxes experience temperature fluctuations, their parts naturally expand and contract. Forged alloys handle this better than other materials because they don't stretch as much when heated and stay stable through these changes. This means less movement between gears that mesh together. The strength against fatigue is just as important though. Regular materials tend to bend out of shape after many loading cycles, but forged alloys keep their original form, which keeps things aligned properly like how planet gears should rotate around the sun gear. Getting the carrier right makes all the difference too. A well designed carrier spreads forces evenly across multiple planet gears so no single point gets overloaded. Without proper stiffness and exact measurements, certain spots will wear down faster and eventually lead to misalignment problems. At the end of the day, what kind of material goes into making the carrier and how it's built determines whether the whole system stays aligned or starts drifting off track over time, affecting both where parts sit and how smoothly power gets transferred from one component to another.

How well parts line up determines how much backlash there is in planetary reducers. Backlash refers to that annoying lost motion when direction changes happen. If all components stay aligned within tiny fractions of an inch, the load gets spread evenly among the planet gears. This cuts down on the angle shift between gear teeth and stops that skipping feeling which wears things out faster and makes positioning less accurate over time. Good design practices matter here. Strong carrier structures help fight off heat related warping problems. Preload mechanisms apply steady pressure along the axis to close those gap spaces where play happens. Take dual gear setups with springs for instance. These keep gears meshed together constantly, so they don't slip past each other but still work efficiently. When done right, proper alignment can cut vibrations down by around 40% in factory settings according to tests run by AGMA in their report number 6010-A19. Getting these connections just right means machines transmit power consistently and repeat positions accurately, something really important for precision equipment everywhere.

Alignment is the primary determinant of transmission accuracy in planetary reducers. Misalignment can lead to a chain reaction of positioning problems and mechanical distortions, increasing wear and reducing precision.

Proper alignment ensures even load distribution among planet gears, reducing backlash and preventing excessive wear or premature failures.

Forged-alloy carriers offer superior grain structure continuity, resisting deformation from dynamic loads and temperature variations, thereby maintaining alignment under stress.

Misalignment in planetary reducers can lead to increased wear, noise, vibration, and ultimately reduce positional repeatability and overall performance.

Hot News

Hot News2026-03-03

2026-03-02

2026-03-01

2026-02-28

2026-02-27

2026-02-13

Copyright © 2025 by Delixi New Energy Technology (hangzhou) Co., Ltd. - Privacy policy